티스토리 뷰

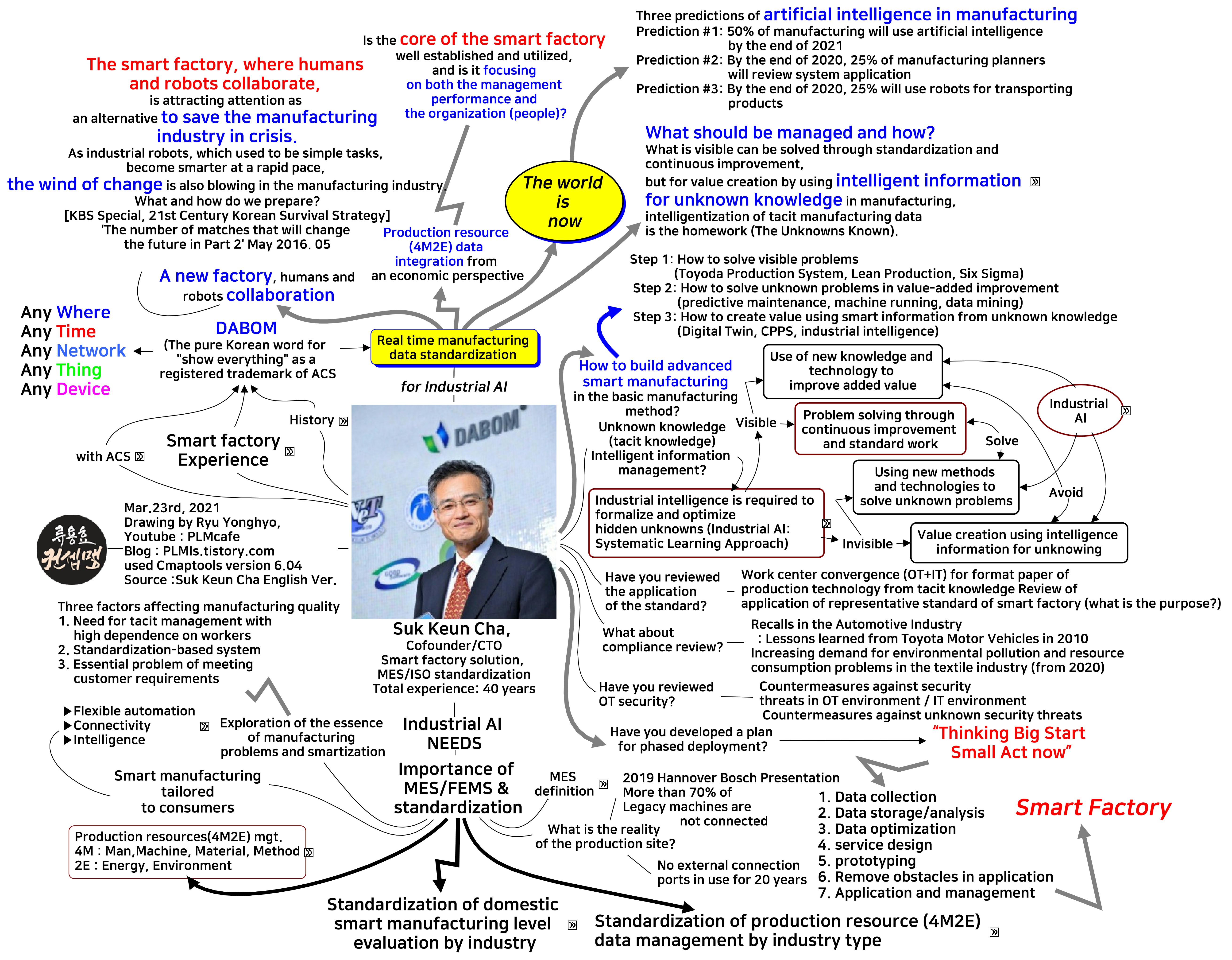

Real time manufacturing data standardization for Industrial AI

류용효컨셉맵연구소 2021. 3. 23. 17:33There is someone who has walked 40 years in the single road of smart factory solutions.

Suk Keun Cha Cofounder/CTO who is leading global ISO standards beyond Korea for MES/ISO standardization. It is not easy to explain the MES/ISO standardization he has followed without looking at his major career.

- Currently Cofounder/CTO of ACS Co.(www.acs.co.kr)

- Successfully completed more than 1,600 MES project including production control system in POSCO and assembly line control in Hyundai-Kia Motors who leading manufacturing in Korea

- ISA ANSI S-95 and MESA Model Standards Commissioner in USA

- ISO TC 184 SC5 Manufacturing Integration Standard Committee

- ISO/IEC JTC IoT Standards Committee

- Chairman of the Smart Manufacturing Plant Operation Standards Subcommittee in Korea

- Small and Medium Business Administration Production Information Support Project Planning Committee (2001~) in Korea

- Connected smart factory planning committee (2014~) Ministry of Future in Korea

- Smart Factory Support Project Planning Committee (2015~) Ministry of Commerce, Industry and Energy in Korea

- Smart Manufacturing Innovation Smart On Shoring Work Group Planning Committee (2019~), Ministry of Small and Medium Business and venture in Korea

- KIAT Industrial Intelligence Planning Committee (2020~) in Korea

In order to create a smart factory concept map, we asked him for the latest released data. He happily gave me detailed data containing the extract. On the paper... And it's difficult to express all the know-how, but I'm going to write down the core content.

I have heard the definition of MES (Manufacturing Execution System).

Through real-time measurement of production resources of 4M2E(Man, Machine, Material, Method, Energy, Environment) that change from time to time, decision-making information, delivery date information for customers, on-site monitoring and analysis information are provided in real time, and through continuous improvement, the overall productivity of the plant is improved and optimized.

- Known Knowns (Continuous improvement and standardization through visualization)

- Zero inventory, zero latency, zero defects, zero downtime

The core of a smart factory is to establish and utilize POP/MES well.

Is this focusing on both management performance and organization (people)?

What should be managed and how?

What is visible can be solved through standardization and continuous improvement, but for creating value through the use of intelligence information for unknown knowledge in manufacturing, intelligentization of tacit manufacturing data is the homework.

- The Unknowns Known tacit knowledge...

I named it Industrial_AI_Cha_Map.

-END-

'맵의 세계(컨셉맵)' 카테고리의 다른 글

| [서평맵] 러닝 SQL (앨런 볼리외 지음, 류수미,송희정 옮김) (0) | 2021.04.17 |

|---|---|

| [서평맵] 초전략으로 승부하라 (추성엽) (0) | 2021.04.04 |

| [시사맵] 메타버스 1편.비대면이 잠자고 있던 메타버스를 깨우다 (3) | 2021.03.22 |

| [리뷰][서평맵]고객이 보이는 구글 애널리틱스(2판) (0) | 2021.03.20 |

| [시사맵] Clubhouse 분석맵 (0) | 2021.03.08 |

- Total

- Today

- Yesterday

- 허성원 변리사의 특허와 경영이야기

- Duarte 데이터 스토리

- 까마귀의 CATIA방법론

- 엉터리 훈장

- 컨셉맵

- Janghee_Lee

- 2030년의 인공지능

- beyondplm.com_Oleg Shilovitsky

- 한국스마트제조산업협회

- 머신러닝 블로그

- 머신러닝 제대로 배우는 법

- 머신러닝 스터디

- 딥러닝 자료모음

- 딥러닝 라이브러리

- 시스템과 문제해결

- 최인정의 자동차 백과

- 전기자동차 사이버교실

- 오토기어(AutoGear)

- 유용원의 군사세계

- Back to the Mac !

- 영어자료

- PLM지식연구소

- 조인스_좋은글

- 멘토프레스

- AudioEnglish_site

- Learning English

- 문화유산 답사기

- 4M(Men, Machine, Material, Met…

- 품질_APQP용어정리

- 사진 문화 망명지

- 마켓 인텔리전스(최신트렌드)

- 타이어 용어

- 모남진 영국생활

- 해외여행 물가 비교

- 야경사진

- 스콧슈만의 사토리얼리스트

- MYSQL

- Katacoda

- R, Python 분석과 프로그래밍의 친구 (by R …

- 윈칠

- 장천

- 전기차

- 모빌리티

- 컬럼

- plm

- PLM리스너

- AI

- KPA

- 쪽지

- WIndchill

- IOT

- 서평맵

- 컨셉맵

- 인공지능

- 자율주행

- 남해

- 두물머리

- PLMcafe

- 월요편지

- 류용효

- 캐드앤그래픽스

- 한장의맵

- 한빛미디어

- 사천

- 한강

- 클라우드나인

- 2022

- 거창대성고등학교

- ChatGPT

| 일 | 월 | 화 | 수 | 목 | 금 | 토 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 |

| 22 | 23 | 24 | 25 | 26 | 27 | 28 |